Address

85 Great Portland Street, First Floor, London, England. W1W 7LT

Phone: (+44) 7735159886

Address

85 Great Portland Street, First Floor, London, England. W1W 7LT

Phone: (+44) 7735159886

contractor of the US$22 billion strategic deep tunnel drainage system project (hereinafter referred to as the DSST project). Dubai Municipality currently requires companies interested in bidding for the project to submit a declaration of qualifications before February 26, 2024. According to industry sources, the list of pre-qualified EPC contractors is expected to be announced before March 11. Subsequently, Dubai Municipality will launch the pre-qualification process for the PPP consortium of the project in the second quarter of 2024 as planned.

The project was first initiated in 2015. After the completion of the feasibility study in 2017, construction failed to start as scheduled according to the original plan. It will not be restarted until 2023, when it received financial support from the US$21.8 billion “Sewage System Plan” approved by the Crown Prince of Dubai. At this point, the estimated total investment in the project has increased from the previous US$12.5 billion to US$22 billion.

Overview of Dubai Deep Tunnel Drainage Project

Dubai Municipality approved the DSST project in June 2023, with an expected investment of approximately AED 80 billion (approximately US$22 billion). Dubai Municipality also previously selected Abu Dhabi’s Tribe Infrastructure Group as chief financial adviser, Britain’s Ashurst as legal adviser, and U.S.-based Parsons as technical adviser. The DSST project is expected to be completed within five years. At that time, this deep tunnel drainage system will replace Dubai’s existing 121 sewage pumping stations that consume electricity, convert Dubai’s existing sewage system from a pumping system to a gravity system, and greatly reduce the cost of the sewage system. operating costs. The tunnels will run 25 to 90 meters underground and are expected to have a service life of up to 100 years, reducing carbon emissions by 30% compared to current sewage systems. The DSST project aims to meet the needs of Dubai’s population over the next 100 years and is in line with Dubai Economic Agenda D33 and Dubai City Plan 2040.

The DSST project is divided into six bidding sections for separate bidding. Currently, four bidding sections (J1, J2, J3, W) have announced part of the project information, including deep sewage tunnels, connecting lines and transportation system parts. The remaining two The bidding section is the expansion and upgrading project of Jebel Ali Sewage Treatment Plant and Warsan Sewage Treatment Plant, and will be tendered separately from the first four bidding sections.

Section J1 includes the northern section of the Jebel Ali Deep Tunnel and the Terminal Pumping Station (TPS). The length of the tunnel in this section is about 42 kilometers, and the length of the connecting line is about 10 kilometers. Among them, the Jebel Ali Deep Tunnel is another deep tunnel drainage project in Dubai. Its tender sections 1 and 2 have been completed in 2022.

Section J2 includes the southern section of the Jebel Ali Deep Tunnel. The tunnel is expected to be extended by 16 kilometers and the length of the connecting line is expected to be 46 kilometers.

Section W includes the Warson Tunnel, Terminal Pumping Station (TPS) and connecting lines. The length of the Warson Tunnel is 16 kilometers, connecting Dubai’s existing Warson sewage catchment area, and the wiring length is expected to be 46 kilometers.

Section J4 includes 120 kilometers of connecting lines.

Among them, the J1, J2 and W bidding sections are invited to bid according to the “design-build-financing-operation-maintenance” model. After completion, the winning PPP contractor will be responsible for operation and maintenance, and the franchise period is expected to be 25 to 35 years. The J3 section will be tendered according to the design-build-financing model and will be operated by the Dubai Municipality after completion. The project request for proposals (RFP) for the above four tender sections J1, J2, J3, and W may be released in staggered order, with a time interval of approximately 6 to 12 months. According to the pre-qualification documents, the bidders for each PPP tender will be a consortium that has passed the PPP pre-qualification, including the sponsor, the general engineering contractor and the operations and management (O&M) contractor.

Domestic and foreign practice of deep tunnel drainage

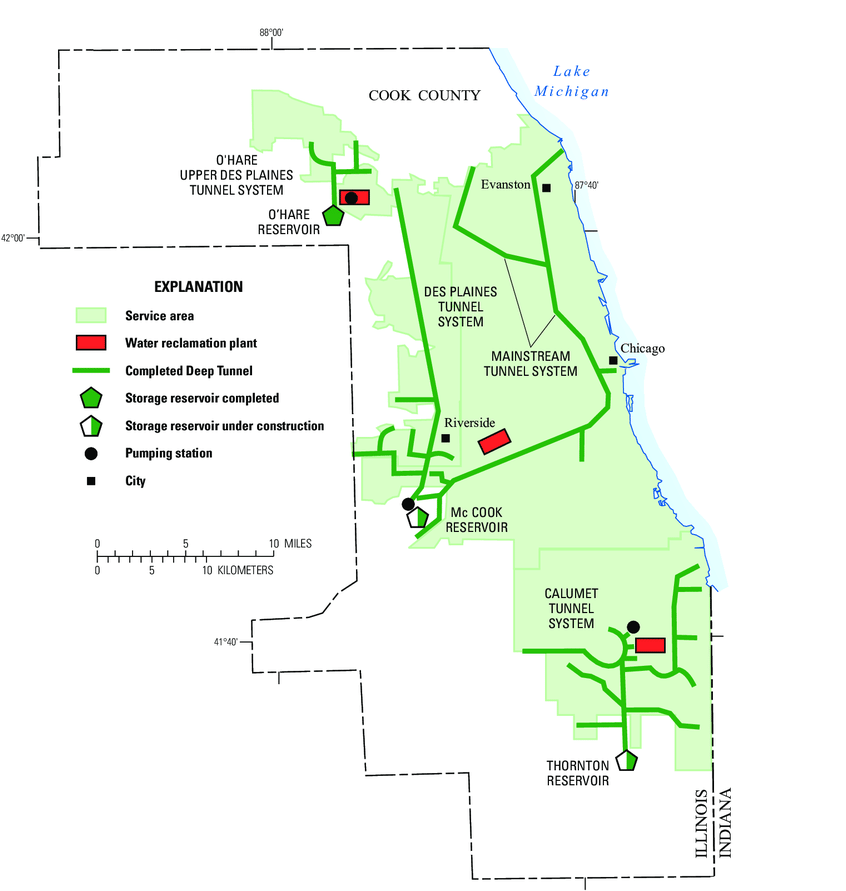

Deep tunnel drainage systems have a long history of research in developed countries and regions, and a number of projects have been planned and constructed. They generally have the characteristics of large project scale, high total investment, long construction period, high construction technology, and high risk factor. The project execution level There are generally significant risks. This type of system is generally buried 30 to 100 meters underground and is connected to the urban shallow drainage system. It plays the roles of sewage collection in the dry season, pollution control in the rainy season, flood control and drainage, etc. without affecting the development and utilization of the urban surface and shallow underground environment. . The following is a brief list of well-known deep tunnel drainage projects at home and abroad as a reference for estimating project costs. The Chicago Deep Tunnel and Reservoir Project (TARP) located in Chicago, USA, aims to reduce flooding in the Chicago metropolitan area and reduce the harmful effects of raw sewage flushing into Lake Michigan by directing rainwater and sewage into temporary reservoirs. . The project began in the mid-1970s and is managed by the Greater Chicago Metropolitan Water Reclamation District. Completion is currently not expected until 2029, with much of the system already operational. During the long construction process, the project has cost more than 3 billion US dollars. In the first phase of the TARP project, approximately 176 kilometers of drainage tunnels were built, with the deepest reaching 110 meters underground. Construction started in 1975 and was completed and put into use in 2006. The second phase of the TARP project is mainly to build a reservoir for flood control and is expected to be completed in 2029. The tunnel can currently hold up to 8.7*10^9 liters of sewage. Since the tunnel was put into use, local sewage overflows have been reduced from an average of 100 days per year to 50 days. Since Sandton Reservoir was opened in 2015, sewage overflows have almost disappeared. This project is located in Kasukabe City, Saitama Prefecture, Japan. It is mainly used to prevent floods and drain water around Tokyo during the typhoon season, and serves as a flood regulating pool. The main body of the project is a tunnel about 6.3 kilometers long, with a total water storage capacity of about 670,000 cubic meters and a total drainage capacity of 200 cubic meters per second. The project started in March 1993, was partially completed and put into use in 2002, and was fully completed in 2006.

Hong Kong Harbor Treatment Scheme (HATS)

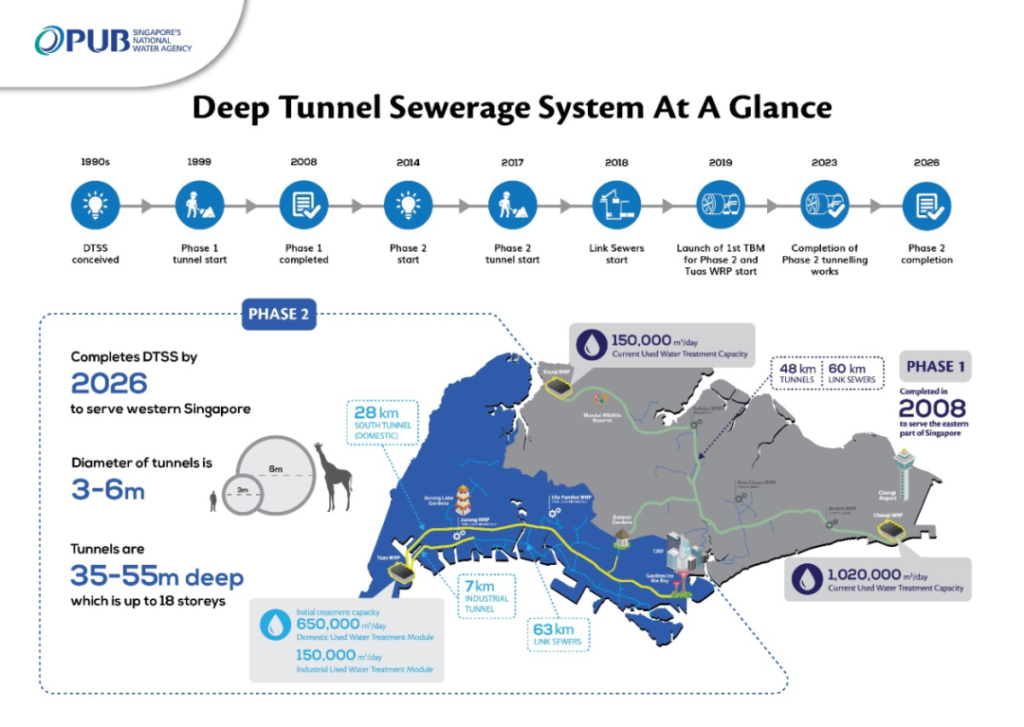

This project is located in Hong Kong, China. It is a sewage treatment infrastructure project carried out by the Hong Kong government in two phases since 1994. It collects and treats sewage in the area surrounding both sides of Victoria Harbor to improve Victoria Harbor water quality. The first phase of the project started in 1994 and was completed in December 2001; the second phase of the project started in 2009 and was fully operational in December 2015. The first phase of the project cost HK$8.2 billion, and the second phase of the project cost HK$17.5 billion. Phase IIB project will build additional biological secondary sewage treatment facilities at Stonecutters Island Sewage Treatment Works. The Hong Kong government needs to subsidize the operating expenses of the project, so a sewage treatment service fee was introduced on April 1, 1995. Singapore Deep Tunnel Sewage Treatment System (DTSS)

This project is located in Singapore. It is a large-scale integrated water conservancy project being developed by the Public Utilities Board of Singapore. It aims to meet Singapore’s needs by collecting, treating, recycling and disposing of wastewater from industry, households and businesses. Long-term demand for clean water. The project design life is 100 years and requires no maintenance. The project’s tunnels, with a total length of 80 kilometers, will transport wastewater to three central water reclamation plants. The project is being developed in two phases. The first phase of the project was completed in 2008, with an investment of US$2.7 billion. The second phase of the project is planned to start in 2016 and is expected to be completed in 2026, with an estimated investment of US$7.3 billion. The total investment in the DTSS project is expected to reach US$10 billion.

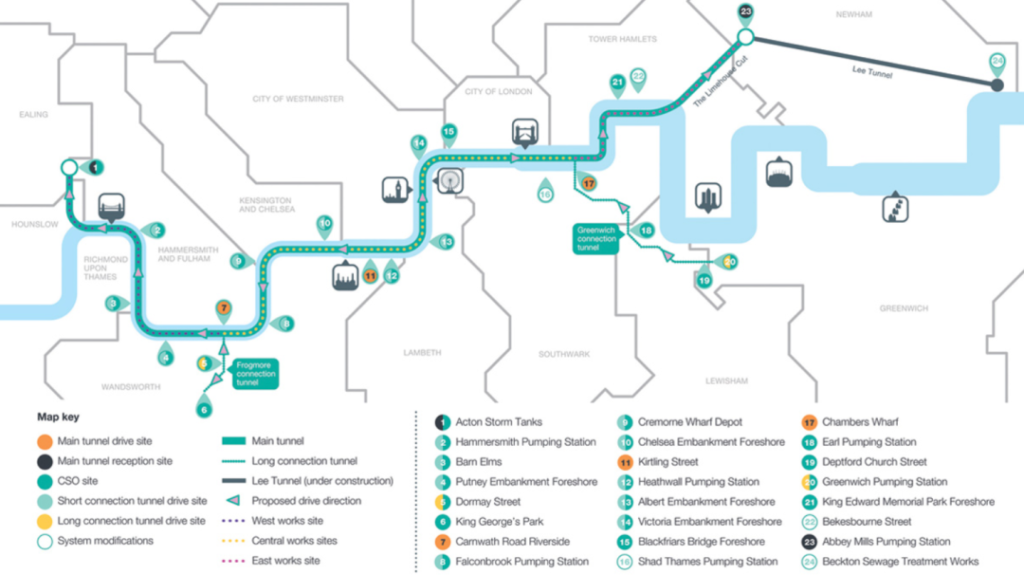

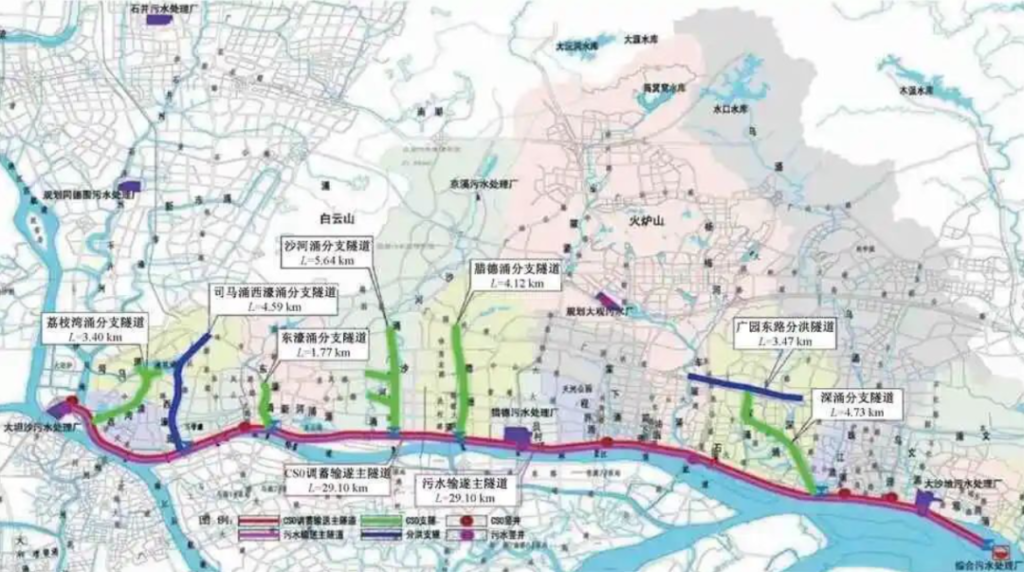

The Thames Tedway Tunnel project is located in London, England . The Tadway Tunnel is a 25-kilometer-long deep tunnel drainage project under construction, mainly located under the tidal section of the Thames River across Inner London. It is used to collect, store and transport almost all raw sewage and rainwater that currently overflows into the estuary. . The project started in 2016, the tunnel excavation phase was completed in April 2022, and it is expected to be fully operational in 2025. The initial estimated capital cost of the project (excluding financing, operations and maintenance costs) totals approximately 3.8 billion pounds, with a further 1.1 billion pounds for preparatory work. The total cost reported in 2021-22 has been revised to £4.3 billion due to progress delays caused by the global pandemic of Covid-19. If cost overruns exceed 30%, the government will have to provide additional equity financing for the project. At present, enterprises in mainland China also have the ability to build such projects. Among them, the Guangzhou Donghaoyong Deep Tunnel System is the first deep tunnel drainage project in the country, and the entire shield tunnel was completed at the end of 2018. The project is constructed by China Tunnel Construction Group. The main tunnel test section is about 1.77 kilometers long. The “one main and seven auxiliary” deep tunnels have a total length of 86.42 kilometers and a burial depth of 40 meters. A large comprehensive pumping station and other related ancillary facilities are installed at the end. The project aims to solve the problems of combined sewage overflow and urban waterlogging in Guangzhou during the rainy season. The project plans to invest 25 billion yuan, and the construction cost is about 289 million yuan/km.

In addition, domestic such projects include Shanghai Suzhou River Deep Tunnel, Wuhan Dadong Lake Deep Tunnel, Shenzhen Nanshan Qianhai Deep Tunnel, etc., which can be used as reference for domestic enterprises. In addition, two cities, Beijing and Chengdu, are also planning deep tunnel drainage systems.

Economics of Overseas Deep Tunnel Drainage Projects

When considering the future economic benefits of overseas deep tunnel drainage projects, the following aspects may be involved:

Agree with government on project revenue forecast

Overseas deep tunnel drainage projects have large investment scales and long construction cycles. The government generally uses the PPP model to seek cooperation with the private sector. Based on this, the common practice for the government to assume the O&M risks of such projects is to provide a minimum income guarantee commitment to the private sector. This requires the private sector and government to agree on future revenue projections from the project. This means that in the planning and design stage of the project, it is necessary to use advanced technical means to simulate and predict various index parameters of the deep tunnel and give a quantitative description to assist in calculating the future income of the project. The accuracy of currently widely used professional drainage model software such as SWMM, Mike Urban, and Infowork ICM is also constantly improving, and the consistency with the actual drainage system can reach more than 80%.

Pay attention to the local government investment capabilities and construction conditions of the project

The investment scale of deep tunnel drainage projects is large, which places high demands on the local government’s investment and financing support capabilities. If the investment and financing support provided by the local government cannot remain stable in the long term, there may be an adverse situation in which work is stopped and delayed during project implementation, or even project execution is forced to be interrupted. In addition, different construction conditions in different regions may affect the design, construction, operation and maintenance of deep tunnels, which in turn affects the unit cost of deep tunnels.

Pay attention to preparing plans to deal with emergencies

The construction, operation and maintenance of deep tunnel drainage projects require a large amount of underground work, and the overall construction risk is high. Therefore, it is necessary to prepare plans for emergencies such as landslides, underground water seepage, and accidental casualties, in order to reduce the delay in project progress and the loss of economic benefits caused by various emergencies.

Technological innovation and cost control

Factors such as the local geological and hydrological conditions of the project, the scale and difficulty of the project, etc. will directly affect the construction cost. This requires the construction party to formulate cost control strategies according to local conditions, control costs by optimizing construction plans, strengthening construction management, innovating construction technology, improving construction techniques, etc., without compromising the quality of the project, and improving the overall economic benefits of the project.